A popular generic and rather vague designation. Bio-based plastics or bio-based plastics are polymers derived from renewable raw materials: corn, sugar cane, cellulose, etc. First of all, they are biodegradable. Secondly, their raw material sources, unlike petroleum-based polymers, are completely renewable. When manufacturers write “bio-based”, they are referring specifically to the origin of the material. What happens to it after use is designated by other terms.

The biopolymer content varies from 10% to 100% in the different models and manufacturers.

BIODEGRADABLE OR BIODEGRADABLE PLASTIC

Biodegradable materials and products are those that, under certain conditions, are recycled by microorganisms. Plastics in this category are of two kinds:

- biopolymers, which themselves are easily recycled by bacteria;

- petroleum polymers with special additives which allow the material to be metabolized by bacteria.

The main difference and advantage of biodegradable polymers over conventional petroleum polymers is the way they are processed. Biodegradable plastic is recycled in chambers with increased temperature, humidity and plenty of oxygen by “settling” bacterial colonies in the recycled mass. Plants for recycling packages and other packaging made of biodegradable polymers are being built in the EU, USA and some other countries, but so far there is no such infrastructure in Russia. Although the production of biodegradable plastic causes much less damage to the environment than traditional packaging, we use only about half of its potential.

Nevertheless, most suppliers focus on this direction. The strategy of some of them is to switch completely to biodegradable plastic of the first type.

COMPOSTABLE, OR SELF-DEGRADABLE PLASTIC

A term to which the definition of “biodegradable” plastic is often (and mistakenly) equated. Only plastics that decompose in nature into CO2, water and biomass in a short period of time and without any special conditions can be called compostable. Some types of biodegradable plastic can also do this, but they take much longer and still leave a chemical residue behind, so they cannot be considered compostable. Compostable plastic always implies “biodegradable,” not the other way around. Self-degradable packaging is the rarest, with only a handful on the market.

RECYCLABLE

All plastics, regardless of whether they biodegrade or not, are suitable for recycling. It is separated from other waste, shredded, washed, and sent for recycling. What you get as a result, and is called recycled plastic (recycled). According to the origin is divided into types: consumer (PCR – Post-Consumer Recycled) and industrial (Post-Industrial Recycled). One of the main rules of recycling: recycled plastic is not used to make the same products from which it was derived. A recycled bottle can become a park bench or building insulation, but it cannot become a bottle again.

Recyclable packaging can hardly be called full-fledged “eco”. Today, almost any plastic, regardless of origin, can be recycled and reused in construction or other industry. The “recyclable” label is more of an environmental minimum than a real advantage.

PCR, PIR – RECYCLED PLASTIC

PCR (Post Consumer Recycled) and PIR (Post Industrial Recycled) are recycled plastics. PIR is most often recycled leftovers or rejects from factories’ own production. PCR is a more expensive option. This is recycled consumer plastic waste. Specialized factories collect and prepare such raw materials and then supply them to packaging manufacturers. The percentage of recycled plastic in a bottle can be anything from 5% to 100%. 100% recycled material contains only bottles in natural color. In dyed packaging the figure is reduced by the proportion of dye content.

“GREEN” PRODUCTION

A great contribution to environmental protection is made by manufacturers who not only make packaging from “harmless” plastic, but also invest in eco-production technologies. The list of such technologies includes: reduced energy consumption, limitation of emissions into the atmosphere, waste-free or combined production (products plus recycling).

A NEW ECO-PLASTIC FROM CELLULOSE AND WATER HAS BEEN DEVELOPED

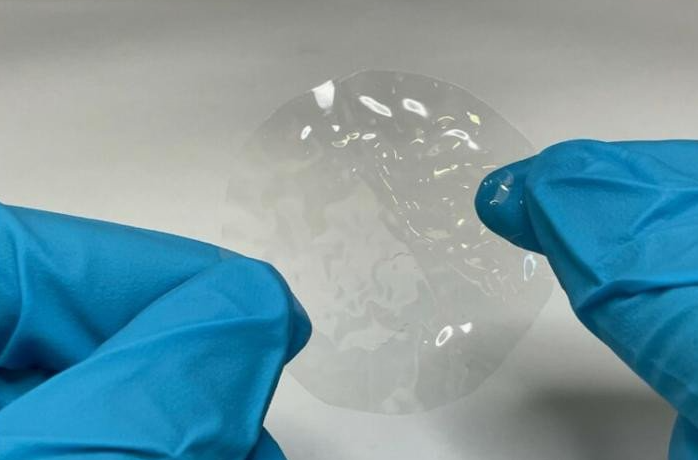

Researchers from the University of Göttingen (Germany) have created a new type of environmentally friendly bioplastic with hydroplastic polymers. It can change shape on contact with water, reports the press service of the university. The study was published in the journal Nature Sustainability.

Plastics are polymers, which means that their molecular structure is built from a large number of similar units linked together. Currently, most plastics are made from petrochemicals, which are harmful to the environment during both extraction and disposal. In contrast, cellulose, which is the main component of plant cell walls, is the most abundant natural polymer on Earth, representing an almost inexhaustible source of raw materials. By slightly changing a small part of the chemical composition of cellulose by adding a “cinnamoyl” group, the researchers were able to create a specific cellulose cinnamate (CCi), a polymer that is suitable for forming a new type of bioplastic with hydroplastic: it becomes plastic upon contact with water.

The new plastic can be shaped using water at normal temperature and pressure. This unique method, known as hydroplastic, allowed the researchers to obtain a wide variety of shapes simply by submerging the bioplastic in water and leaving it to dry in the air. The resulting shapes were preserved for a long time and could be remade again and again into a variety of 2D and 3D shapes. Although the plastic should not be used for direct contact with water because it will lose its shape, it can hold water and be used in wet conditions. CCi bioplastics have shown high mechanical properties compared to currently commonly used plastics.

The hydroprocessing process avoids costly and complicated equipment and harsh processing conditions. This environmentally friendly method greatly simplifies the production of plastics, making them more economical and environmentally friendly to recycle. Such bioplastics can be used in biology, electronics and medicine.